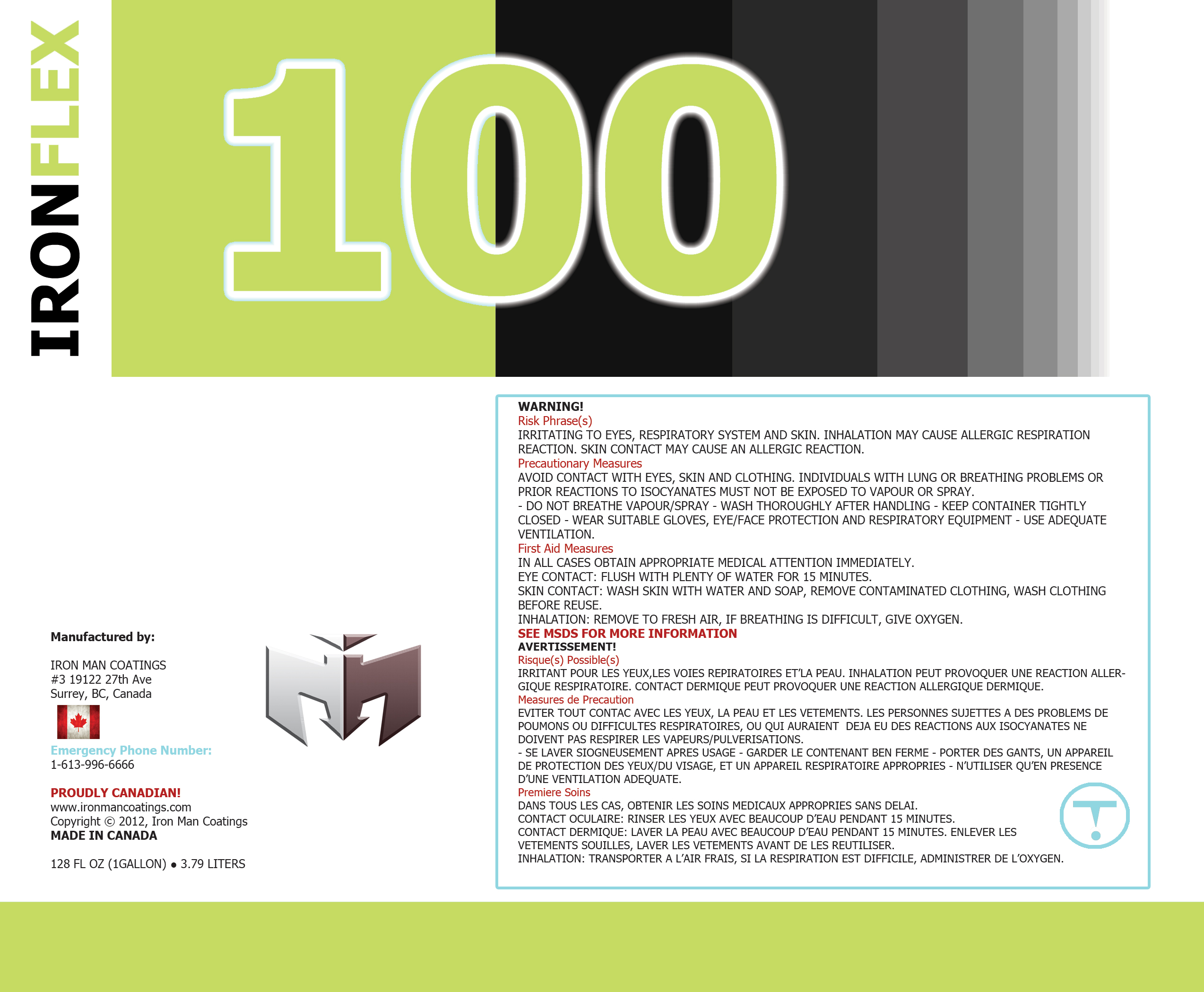

Welcome to Iron Man Coatings

IMC SEE THE LINE-UP ADVANCED TECHNOLOGY

GET CERTIFIED OUR HISTORY REACH OUT

Our Products

Iron Man Coatings® brings value to our customers through our on-going product research and development, manufacturing expertise and superior customer service. Our strict production process encompasses:

• Time and resources allocated to product development, testing and manufacturing

• A strict code maintained in the laboratories and manufacturing facility

• Top quality raw materials

• All-inclusive customer service from processing orders efficiently to end-user technical support.

We manufacture our polyaspartic coatings in Vancouver, BC, Canada.

The most thorough, hands-on training in the industry. Come and install a couple of garage floors with the most knowledgeable applicators in Canada. We offer the only private training sessions available, and we train installing in residential garages, not in a classroom / warehouse. We manufacture the highest quality polyaspartic materials.

Unique and Superior Properties

• One-Day Installation with Next-Day Return to Service, foot traffic in just 2-4 hours

• 3-4x More Abrasion Resistant than Epoxy & Urethane Systems

• Low Temperature Application (-30f to 150f)

• 100% UV Clear with Excellent Color & Gloss Retention

IRONFIX-RAPID REPAIR® is an extremely rapid set, high-strength, low viscosity concrete crack and spall repair polymer. Our two part polymer system repairs deeply spalled concrete, broken control joints, and cracked concrete surfaces. The products dries in 10-15 minutes (even in sub zero conditions).

Benefits and Features

• Quickly repairs cracks or spalling

• Short downtime

• Quick drive-on time

• Creates a seamless look

• 1:1 mix ratio

• Application as low as -30ºc

• High impact resistance

• High tensile strength

General Physical Characteristics

• 60% solids

• Shelf life - One year

• Hardness (ASTMD2240) - Shore D 70

• Mix ratio 1:1

• Tack free 4-5 minutes

• Tensile (ASTM D412) - 4500

• Tear Strength (pli ASTM 624C) - 560

• Elongation (D124) - 8%

•Processing Temperature - 19ºc

© 2019 Iron Man Coatings. Inc. All Rights Reserved.